Premier Automation can integrate new robotic automation systems and/or upgrade existing robotic cells.

Premier Automation designs and implements automated robotics systems for industrial OEM and end user customers. Automated robotic systems are an increasingly versatile, safe, and cost-effective solution for a broad range of industrial applications. Our engineering team has the automation and process control experience to provide our customers with unique, highly efficient robotic solutions that streamline production, improve efficiency, and reduce operating costs.

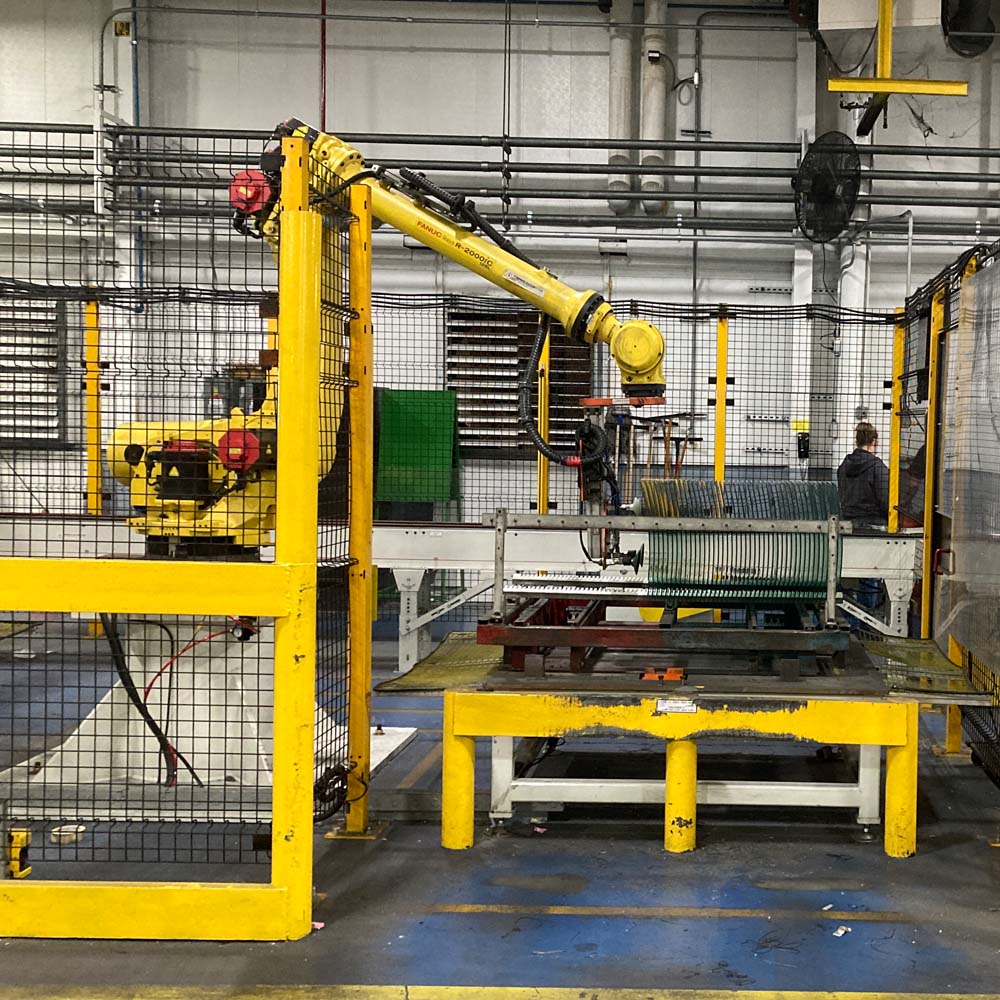

Material Handling

Material handling is a task that is prone to several complications, especially if manual operators are involved. Bringing technology into the mix can straighten things out and close-down common loopholes. Robots in particular can assist with the task and can carry out operations such as parts transfer, automated storage, palletizing, etc.

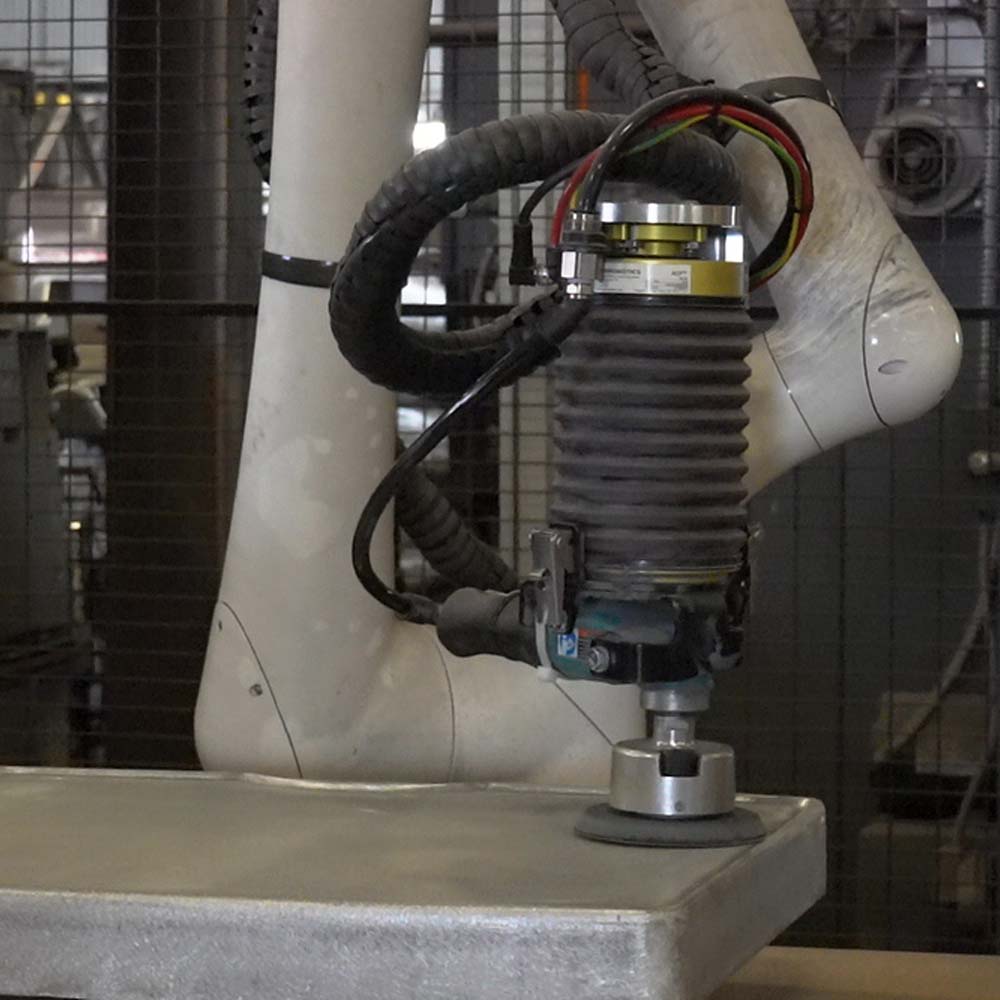

Material Removal

When done by hand, material removal can suffer from inconsistency, and pose an ergonomic risk to operators. Buffing, grinding, polishing, deburring, de-flashing, sandingMaterial Removal, and drilling can be efficiently performed by robots to ensure quality and improve health and safety.

Palletizing

Premier Automation specializes in innovative palletizing automation solutions. Our engineers take the time to understand your unique system, and offer a customized solution that will provide the greatest benefit to you.

Custom Process

Not sure if you have the right equipment to match the robotics system you have in mind? Premier Automation can help you design, specify, and assemble a custom processing equipment.

Custom Assembly

Assembly robots can greatly expand production capabilities, and bring down inefficiencies within manufacturing processes, instantly bringing companies at par with the competition.