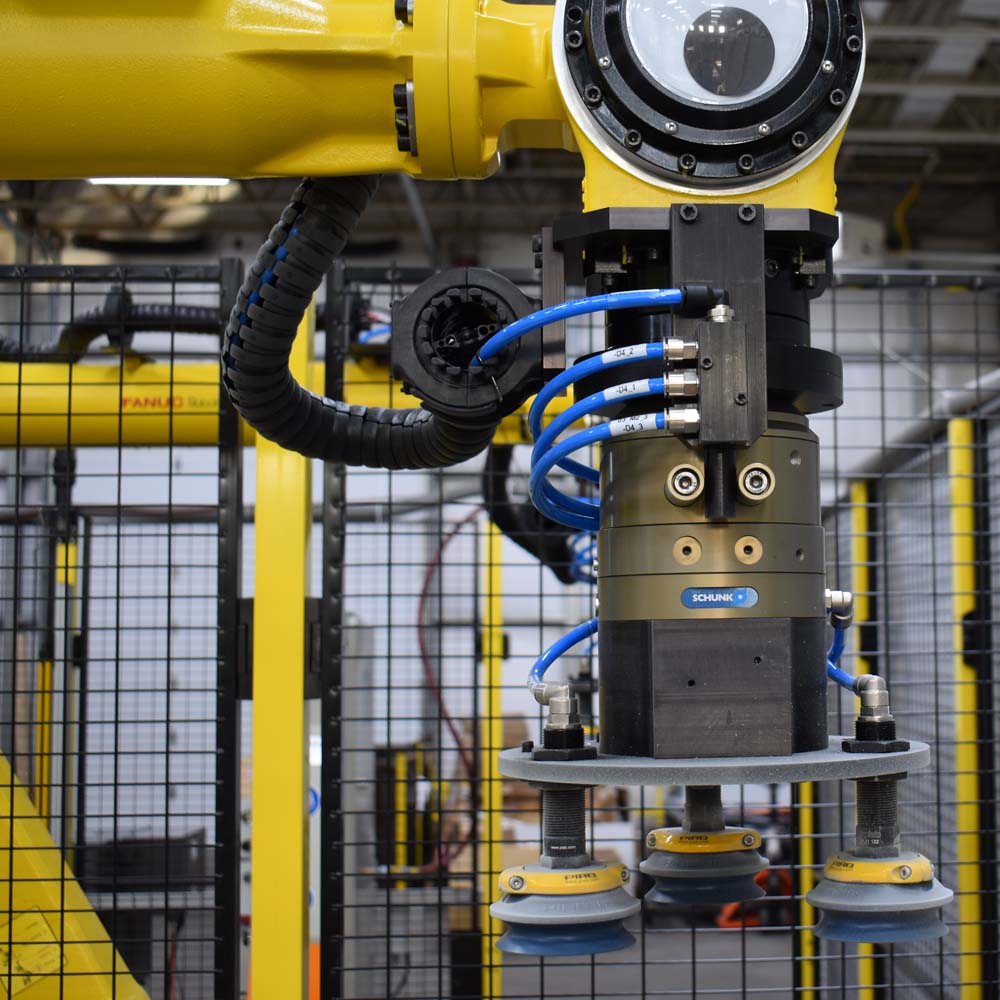

Robotic Laminate Glass Finishing System

This customer manufactures a wide range of glass products for the automotive industry. This facility’s primary product was automotive sidelite windows. Future flexibility and ease of switching between pre-programmed parts or adding new parts to the system was the highest priority for this customer. Specific challenges for this project were:

- The glass parts are concave with variable radius of curvature on the picking surface

- The glass parts have incredibly complex & diverse geometry that needs to be trimmed

- Unload glass from racks without any glass-to-glass contact

- Trim 100% of perimeter of glass to within specified tolerances

- Develop a new part teaching process that is easy for the operator and repeatable

- A compact footprint for the cell, consisting of:

- A Fanuc R2000iC/125L robot to unload glass from racks

- Two Fanuc M710iC/45M robots to perform the grinding operation

- Another Fanuc M710iC/45m pick and place robot to deliver glass to the next stage of the process

- Two rack infeed locations to allow continuous operation of the cell while a fork truck driver removes the empty rack and introduces a new one to the system

- Two floor mounted belt grinders with dust collection system

- Each robot was equipped with a custom designed vacuum tool featuring a Schunk DDF rotary union for ease of routing cables and airline, and an Igus Triflex cable management solution

- Fanuc iRVision was used to locate the parts accurately before grinding

Impact to Customer (outcomes & benefits): Key functionality and enhancements to the system include:

- Utilization of Fanuc Roboguide simulation software and CAD to path programming to train the trim program on each new part

- Improved quality control of parts, with less scratches/defects from operators handling the glass, and a more uniform trimmed edge.

Result: Premier Automation delivers a custom automated solution that meets the customer’s objectives of increased throughput, reduction of scrap loss, and a flexible system to accommodate a range of future parts/products.