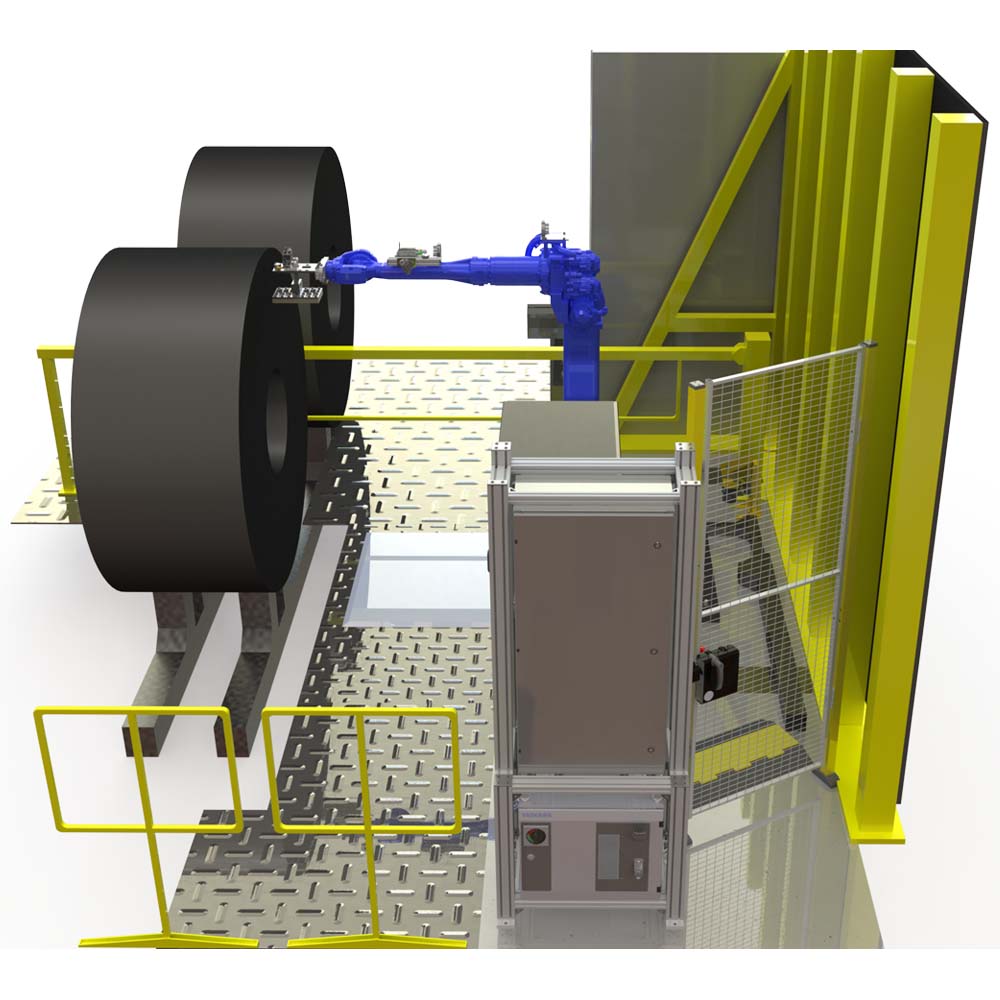

Robotic Label Placement for Steel Coils

Project Summary and Challenge

Premier Automation provided a Robotic labeling solution for the largest flat-rolled steel producer in North America. Their team looked to have an automated solution to print and affix two labels to their steel coils as they came off the Tandem Cold Mill (TCM). This process was currently being done manually by a single operator and put the operator close to process equipment. The goal was to improve safety and improve coil tracking both internally and externally by verifying the label placed.

Project Summary and Challenge

Premier Automation provided a Robotic labeling solution for the largest flat-rolled steel producer in North America. Their team looked to have an automated solution to print and affix two labels to their steel coils as they came off the Tandem Cold Mill (TCM). This process was currently being done manually by a single operator and put the operator close to process equipment. The goal was to improve safety and improve coil tracking both internally and externally by verifying the label placed.

This customer manufactures coils ranging in width and outer diameter. The following design constraints had to be accommodated:

- Accommodate coils ranging from 34” to 78” in diameter.

- Accommodate coils ranging from 34” to 72” in width.

- Verify the label placed matches line information from the mill.

- Be able to place overtop of “laps” on the Inner diameter of the coil caused from the rolling sleeve.

- A floor mounted Motoman GP-35L robot.

- A custom manufactured tool for picking 6” x 10” labels and placing on curved surfaces.

- A custom printer enclosure from Fox IV Technologies equipped with a Zebra Ze500-6 print engine with media rewinder and active peel.

- Area scanners, safety mats, and locking door interlocks for system safety.

- Robot motion path programs were generated to identify the outer diameter and width of coil present, pick the label from the printer, place on the inner diameter and outer diameter of the coil, and scan a barcode on the printed label for coil verification

- Process adjustments for robot speed and motion path can be made through a local HMI.

Benefits:

- The system improves safety by keeping the operator clear of the process equipment.

- The system improves internal and external tracking of coils through a 3-factor verification process. This is done through the robotic scanning of the coils, barcode scanning, and comparison to information from the production line